2014 has ushered in a major increase in the new and rebuilt induction furnace sales for Meltech Ltd with around one system being despatched every three to four weeks.

The introduction of brand new UK designed and built Inverter power supplies and tilting furnace bodies has provided a welcome increase in sales, adding substantially to the second hand rebuilt furnace market to which Meltech is already renowned. Notable new equipment sales have included a 500kg 375kW system for Durable castings Ltd in Chester, a 550kW 500kg system for Newby foundries in Wednesbury and a 750kW twin bodied 1,000kg system for De Sweemer in Belgium.

The rise in new equipment sales has resulted from a five year development strategy which has introduced products which are technically advanced while being very easy to use and maintain , as Steve Macey Joint managing Director explains “Our remit was to iron out the fundamental design problems found in the second hand machines we rebuild , the technology we apply to our new induction furnaces addresses those problems and results in a product which is reliable, very easy to use and maintain while offering features which are unequalled elsewhere in the small furnace market”

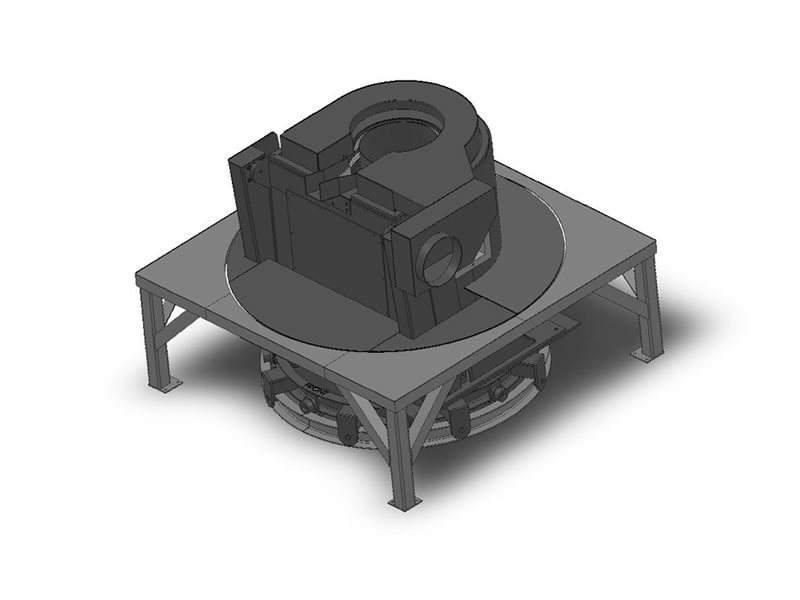

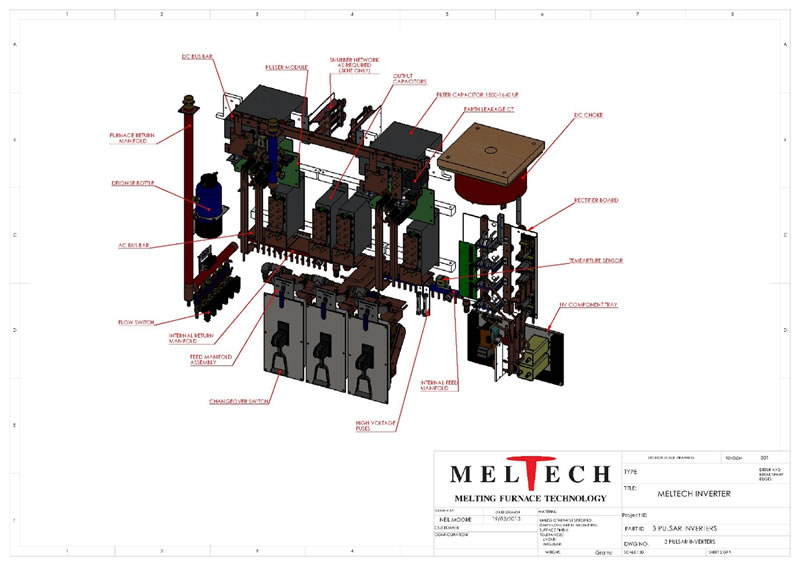

The range of new equipment includes Mag-Melt floor standing crucible furnaces up to 150kg capacity and hydraulic tilting furnaces up to 1,500kg. All furnaces in the range utilize the same air cooled shunt gap technology for efficiency and simplicity. The Pulsar inverter is available up to 750kW based on the Parallel circuit but with a hybrid voltage fed controlled rectifier for near unity power factor and a wide coupling range. Internal closed circuit water cooling systems have also been enhanced by means of sacrificial anodes, de ioniser system with electronic conductivity monitoring and colour coded hosing with high temperature/ low flow LED indicators for all inverter return circuits.

The advantages and features of the system cannot outwardly be appreciated unless a detailed investigation is made, the attention to detail applied by the system designers becomes very clear to the furnace users once the machine is put into everyday use, simple things like water circuit traceability and indication , controlled rectifier protection and concise user operator panels with LED back lit analogue metering only add to a long list of features which are not always available elsewhere which add weight to the manufacturers claim “it’s the Advantages you can’t see that give you the benefits you can”

Since the introduction of the very first Mag-Melt furnace back in 2010, 22 new machines have been sold to countries as far afield as Germany, Poland, Belgium, France, The Netherlands and the UK.