A unique understanding of the problems associated with most types of coreless induction furnace has driven Meltech to develop a system with simplicity and efficiency in mind, careful attention to detail has resulted in the equipment being very easy to live with and maintain.

With power ratings of 50kW up to 750kW with frequencies of 200 to 3,000Hz the Pulsar inverter is ideally suited for the efficient melting of Ferrous, Copper based and Aluminium alloys within the small to medium foundry environment.

The Pulsar IGBT system incorporates the latest in transistorised technology with digital micro processor control for the efficient heating and melting of ferrous, non ferrous and precious metals.

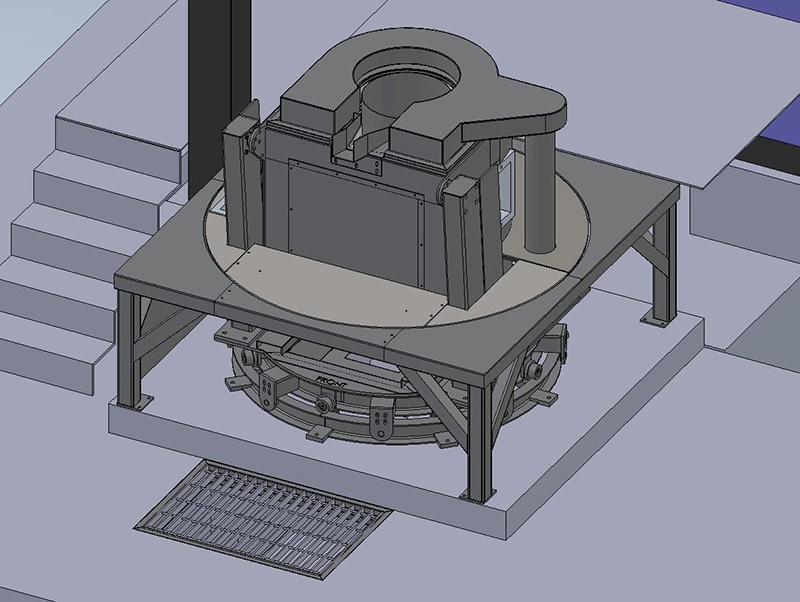

All Mag-Melt tilting induction furnace bodies offer a rugged design and utilize shunt gap technology to provide a compact yet economically priced steel constructed furnace body with a capacity range of up to 1,500kg ferrous or 500kg of Aluminium alloys.

For smaller non ferrous alloy melting applications the Mag-Melt “C” crucible furnace body has the operational features of the larger tilting furnace body incorporated into a drop coil arrangement which has eliminated the need for trenches or pits, common to other brands of crucible furnace.

Carousel systems can be employed on any new or existing tilting furnace body to allow it to rotate, while our pre-tilt systems offer the ultimate in operator control, superior to a traditional double axis tilting furnace.

Compact rollover furnace bodies designed specifically for the efficient melting and casting of precision products for the lost wax / investment casting industry, these furnace bodies can easily be connected to all brands and specification of inverter system.