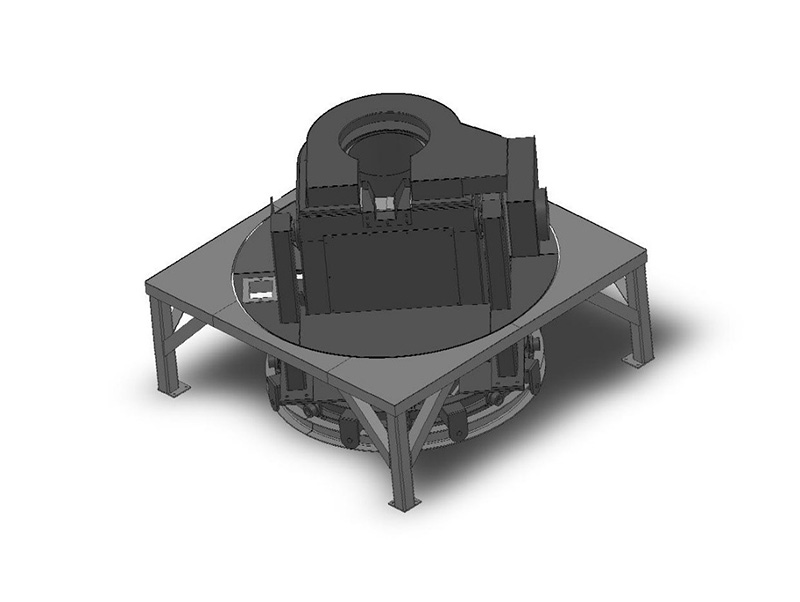

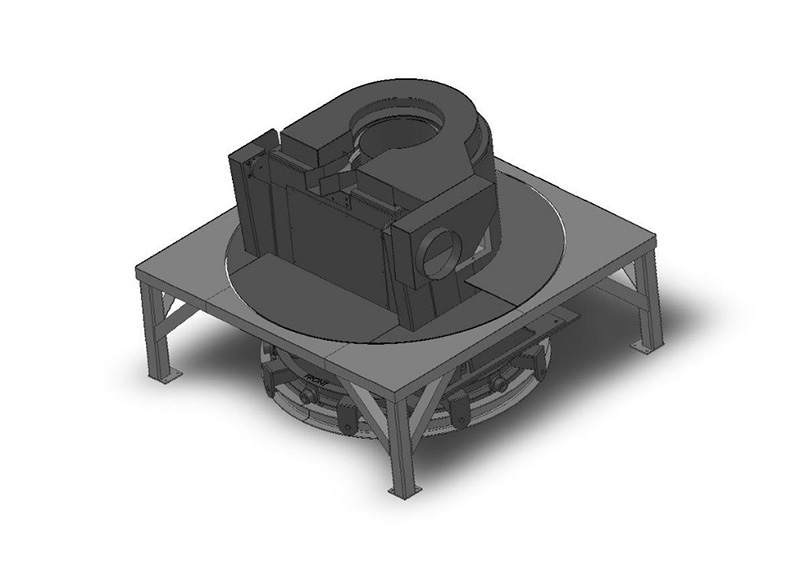

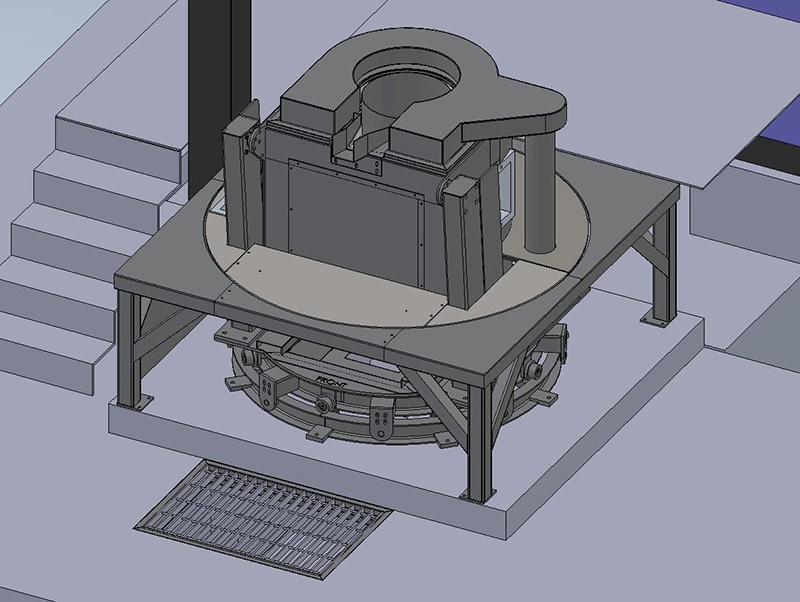

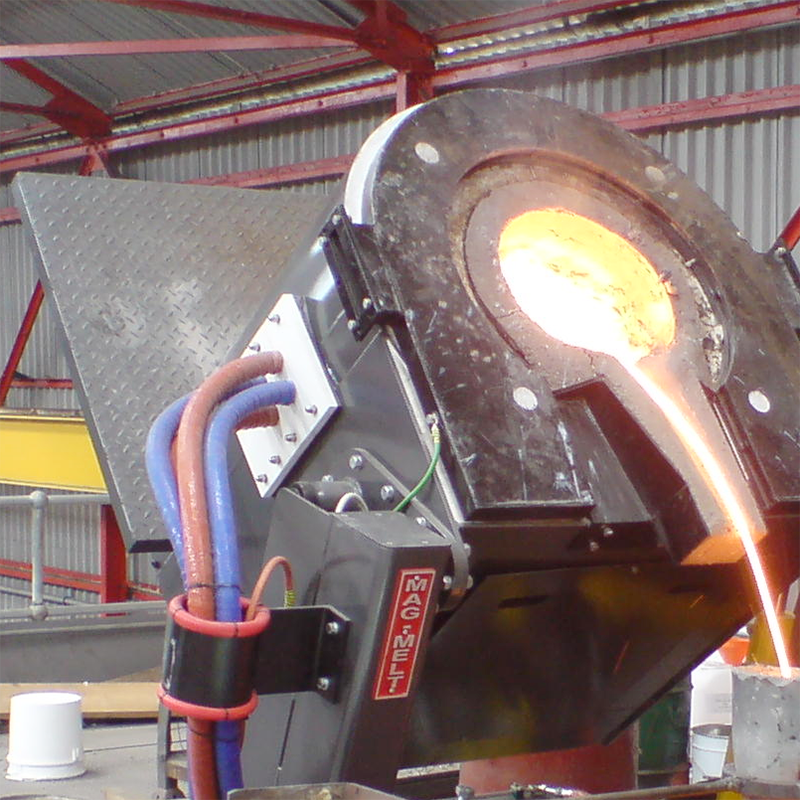

Carousel Furnace Systems

The carousel system can be employed on any new or existing tilting furnace body to allow it to rotate , this hydraulic or electromechanical system rotates the furnace prior to pouring the metal, Typical applications are when a single furnace is providing molten metal to different production applications where a ladle pour and a launder pour may be required at different times and in different positions. Ideally this system can be adapted for multi process situations where space does not allow the use of two separate furnace bodies such as atomizing plant or continuous casting.

Features:-

- Hydraulic or electromechanical rotational indexing allows pour axis to be chaned in seconds.

- Remote operation which allows the operator to be at a safe distance from the process.

- Captive rotation rings allow the tilting furnace assembly to be simply and safely rotated without the risk of damage to the furnace or associated plant.

- Refractory lined spill tray which prevents damage to associated plant should a metal run out occur.

Advantages:-

- Can remove the need for two or more dedicated furnaces.

- Pouring position can be rotated quickly.

- Reduced launder lengths can be achieved.

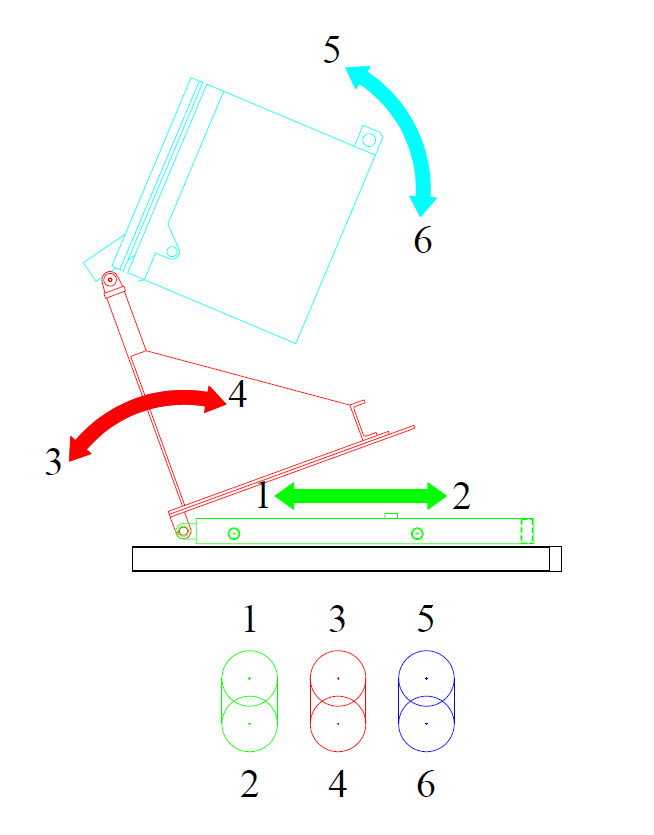

Pre-tilt Furnace Systems

The Pre-tilt system can be employed where fine control of the pouring position, speed and pouring arc are required. These systems offer the ultimate in operator control and are superior to a traditional Double axis tilting furnace and are typically used on atomizing plant, investment casting and multi pour scenarios where static moulds are used.

Typically a pre-tilt system can deliver metal directly and accurately into a receiver less than 100mm in most scenarios without the need for launders.

In addition to the standard geometary of a normal tilting furnace body there is the choice of one or two additional axis as shown below.

- The blue axis (5 & 6) is the standard axis which is common to all standard tilting furnaces and gives pour rate control.

- The red axis (3 & 4) tilts peed the whole furnace foreward by up to 25 degrees allowing the furnace to be positioned over the pouring point offering clearance for the mould, atomizing chamber or similar.

- The green axis (1 & 2) enables the whole furnace assembly to slide forward and backward allowing the operator to adjust the furnace position to compensate for changes in the arc of the pouring metal.

- The green axis (1 & 2) can also be engineered to provide side to side motion instead of the forward / reverse as shown.

The combination can combine all three axis or the red axis and one other dependent on the application and suitability.

These systems are hydraulically operated and tailored to suit each application, they can be engineered to fit all sizes and makes of tilting furnace body, please call our technical department for specific applications and details.

Main advantages:-

- Ultimate pour position and speed control throuought to pouring cycle.

- Allows the furnace to pour directly into bulky or obstructed receivers.

- Allows the furnace body to be drawn away from the pour position to allow for mould , tundish change, metal chaging etc.

- Reduces metal overspill.

- Virtually maintenance free.

- Eliminates the need for launders.